5 Most Common Problems with the Creality Ender 5: Troubleshooting Guide

5 Most Common Problems with the Creality Ender 5: Troubleshooting Guide

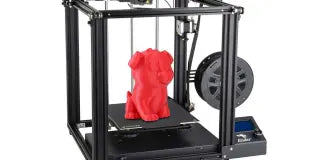

The Creality Ender 5 is a well-loved, affordable printer that is easy for most beginners to use immediately after setup. However, no printer is perfect, and numerous Ender 5 owners have reported many of the same issues both out of the box and after consistently achieving good prints. If you run into any of these common printing problems, try our easy solutions.

We always recommend having a few test prints ready when troubleshooting to check that any adjustments won’t affect other print qualities.

5 most common Ender 5 problems

- Stringing

- Z-axis misalignment

- Skipping

- Uneven layers

- Blobs and blemishes

Stringing

By far the most frequently reported problem among Ender 5 owners is stringing, which is characterized by clearly identifiable—you guessed it—strings that span open spaces in the print. When moving from one point to another, the machine’s nozzle should only extrude filament according to the model file, but a few things can go wrong and cause web-like strands of material to mess up a print.

Troubleshooting

1. Increase retraction distance

Retraction refers to the process in which the printer pulls back the filament after deposition to ensure that the correct amount is heated and extruded. Poor retraction settings can lead to stringing if the filament isn’t sufficiently pulled back before moving to the next printing point.

Slightly increase the retraction distance and try a small retraction test print. For most makers, small adjustments to retraction is sufficient to avoid stringing. However, if you find that you have to increase retraction too much to avoid stringing, which can lead to other problems like spotty deposition, you may have to adjust a different setting.

2. Decrease print speed

An overly high print speed can cause the nozzle to move too quickly between points on the print, which can lead to stringing as the filament doesn’t have time to set.

A variety of factors influence how high or low your print speed should be for optimal deposition, but many makers find that slightly decreasing print speed can give the filament enough time to melt properly before moving to the next part of the print.

If you are switching between filament types or thicknesses, we recommend running a short test print to check stringing, as minor speed adjustments may be necessary under different print conditions.

3. Adjust temperature

Typically, filament that is extruded an overly high temperature will tend to “drip” or string around the print. Slightly lowering the temperature can fix this problem.

Z-axis misalignment

Another commonly reported issue for the Ender 5 is characterized by the nozzle dragging through the filament as it is being extruded or crooked prints—both of which can be attributed to wonky Z-axis alignment.

Troubleshooting

1. Manually adjust Z-offset

First, ensure that the power cord is disconnected before making any manual adjustments to the machine.

Then, manually level the bed according to our bed leveling guide or Creality’s instructions. A correctly adjusted Z-offset will allow the nozzle to evenly deposit filament directly onto the platform without dragging or stringing.

2. Change the slicer settings

Similar to manually leveling the bed, you can use the slicer settings to digitally calibrate the Z-offset and save these settings for future prints.

First, ensure that the filament and bed are heated.

Next, move the print head to the center of the bed and place a piece of paper beneath it.

Navigate to “Prepare” and select “Move Axis.” Select “Z Axis” and adjust it in 1 mm increments until the nozzle just touches the paper. You should be able to move the paper with minimal resistance, but it should not move freely under the print head.

Then, make smaller adjustments until there is almost no resistance between the nozzle and the paper.

Take the total adjustment distance and navigate to “Control” > “Z Offset” to enter and save this new setting. After digital calibration, always run a small test print.

Skipping

You may find that there are gaps or skipped layers in your print, and this issue is more widely observed when makers try to print larger models. People have reported several probable causes for this issue when using the Ender 5, including poor extrusion.

Troubleshooting

During extrusion, the print head exerts tension on the filament and pushes it through the hot end. The components that carry out this process may not be capable of providing adequate pressure to consistently extrude the filament. Depending on the severity of this issue, you may be able to fix it by hand.

1. Adjust extrusion

First, try tightening the extruder arm by adjusting the screw around which the extrusion assembly pivots. Then, slightly increase the extrusion rate (3–5%). This is a good fix for minor skipping issues but may not be sufficient for frequent or large layer gaps.

2. Add external pressure

If the problem persists, swap the filament and add external pressure during extrusion. When swapping filament, compress the spring. This causes the bearing to exert more pressure on the filament during extrusion and the spring to rest in a more compressed state. Because you are applying mechanical force to the parts, you will have to do this every time you swap filament, but it should provide adequate pressure to initiate even flow if this issue isn’t persistent.

Note that if you have to consistently apply external mechanical force to ensure proper printing, it is likely that you may need to replace some components or get the printer professionally serviced.

3. Swap extrusion gears

If these fixes don’t work, you may have to purchase new extrusion gears with better grip. Always take care when changing any parts in your printer if you are not getting it professionally serviced.

Uneven layers

Troubleshooting

One persistent complaint about the Ender 5 is inconsistent filament deposition, causing uneven layers. Unlike skipping and stringing, uneven layers can be observed even in fully completed prints that can simply exhibit changes in layer thickness or layer shifting.

1. Check the bed temperature

Some makers use a temperature threshold setting, also known as bang-bang heating, on the Ender 5 that can induce expansion and contraction over the course of some models, particularly those with long print times. Depending on the material and type of model you’re printing, PID heating might work better.

Consider implementing a PID algorithm to maintain consistent heating along the course of the print.

2. Decrease print speed

If inconsistent temperature is not the culprit, it is likely that the print head is moving too quickly on some parts of the print, leading to thinner layers.

Decrease the print speed very slightly and attempt a few test prints, such as layer shifting torture tests, to check the optimal speed for the filament you’re using.

Blobs and blemishes

No one likes dealing with zits or blemishes, and unwelcome blobs of filament on the surfaces of many Ender 5 owners’ models are no exception. While blobbing is typically considered a surface defect that can be addressed with post-processing techniques like sanding, it can still affect the functional integrity of some prints especially when multiple parts are printed for use in a larger model.

Troubleshooting

1. Clean the nozzle

Sometimes, blobbing occurs because of a partially blocked nozzle. Throughout the print, this blockage can lead to varying amounts of built-up melted filament to extrude all at once, causing bumps in the layer.

While the nozzle is still warm, wipe it down with an alcohol wipe or slightly damp cloth. The steam and movement may be enough to loosen small blockages. Debris around the tip of the nozzle can be removed using a wire brush or needle.

If a clog is further up the nozzle and a needle or other small, thin object isn’t sufficient, try performing a cold pull (see our detailed guide for more information: How to Fix Clogged and Leaking Nozzles).

2. Lower print speed and temperature

To deal with minor overextrusion, which is another common cause of blobbing, lowering the print speed and temperature in small increments (by 5 mm/s and degrees, respectively) can yield a smoother print.

3. Adjust retraction distance

Fine-tuning the retraction distance can help reduce the amount of filament left over from the previous extrusion event as the nozzle moves around the print.

Decrease the retraction distance slightly and try a test print. Sticking with small adjustments is key as over-adjusting retraction can lead to stringing.

Leave a comment