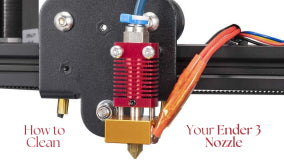

How To Clean Ender 3 Nozzle

All the various parts of a 3D printer contribute vastly to the creation of a model, but the nozzle is perhaps the most important part of the printer. It is where the melted material leaves the hot end. The nozzle is very important because it affects the extrusion of the printer and if the nozzle is not functioning properly, it can lead to a host of printing problems.

Nozzles don't last forever, they deteriorate over time, most especially if they become unclean, clogged, or overused. Although the longevity and performance of your nozzle is determined by its material, diameter, and other characteristics, it is also crucial to ensure that you clean the nozzle of your printer on a regular basis and keep it in good condition alongside other hot end components on the printhead assembly, this way you can extend the lifespan of your nozzle. The Ender 3 printers come with a 0.4mm brass nozzle by default, which has an M6 thread and fits in the heat block.

If you are unfamiliar with this component and how to clean it, you don't have to worry. In this article, we would go over how to clean your nozzle to avoid any problems in the future as well as how to remedy any issues that may cause your printer to stop working. Let's begin!

Identifying the Issue

Before we go into cleaning options for your nozzle, we would like to determine if your nozzle is actually the cause of the problem. A dirty nozzle can create a number of issues, some of which we've outlined below. We've also included some things to look out for before assuming the problem is with the nozzle for each one:

- Nozzle picks up printing material

When your nozzle accidentally picks up some of the laid-down material as it moves across the layer. This problem is usually a result of the nozzle. Be sure you have a proper Z offset and a level bed before you can be certain that the nozzle is the origin of the issue.

- Missing first layer

When you start printing and notice that no filament is being extruded from the nozzle for the first layer, it is possible that a blocked nozzle is the cause of this. However, you should make sure the issue isn't due to the extruder, the Z offset setting, or an uneven bed.

- Inconsistent or uneven extrusion

Inconsistent extrusion usually looks like your printer can't keep up with the material being extruded. It extrudes material in rapid bursts when it should be extruding an even amount of material consistently. Check to see if the issue is caused by a wet filament or the extruder's stepper motor (specifically, its power).

- Hot end jam

Hot end jams frequently appear to be caused by filament being stuck or trapped in the hot end's middle and lower sections. Because the nozzle is a part of the hot end, it could be the source of the jam, but make sure the hot end path is free and not the cause of the problem.

- Print is missing

If you start printing a model and come back to " completed" with only a few printed layers or no printed layers at all, the cause of this could be the nozzle. Nevertheless, it is important to check that your filament diameter is accurate and the print temperature is within the filament material's range and that the extruder is spinning properly (it’s okay if no filament comes out, this is just to make that the extruder motor is working well.

- Under extrusion

This is similar to inconsistent extrusion; it is however a milder variation that results in prints with visible gaps. Check for damp filament, sock extruder tension, or a rough filament route as possible causes of this problem.

While cleaning your Ender 3 nozzle is most often a good idea, as we have earlier said, it is critical to diagnose the nozzle as the source of the problem first because cleaning your nozzle may not always be enough to solve the issues you might be experiencing. When trying to solve a printing problem, it's a good idea to think about all the possible causes, starting with the easiest and then working your way up. Look into each conceivable cause to uncover the true culprit.

Ender 3 Nozzle Cleaning

Now that you are confident that the printing issue you're having is a result of a dirty nozzle, we can move on to the best cleaning methods.

- Exterior waste matter

Waste or debris on the nozzle's exterior is the most evident of all nozzle issues. The waste is usually excess printing material that is adhered to the nozzle during printing. While the problem is nearly always caused by a low nozzle, especially when printing the first layer, the problem is compounded because materials attach easily to each other. Basically, as the filament flows out of the nozzle, some stick to the side and as more filaments flow out, more catches on the original material that clung to the nozzle's exterior.

Solutions

- Remove the two screws that hold the fan shroud in place and heat up the nozzle to the plastic’s required temperature (200°C for PLA).

- While the nozzle is still hot, clean it with a moist cloth or an alcohol wipe. This may produce steam, but it will effectively remove any material stuck to the nozzle.

- If this doesn't work, remove any leftover debris from the nozzle with a wire brush, tiny blade, or needle.

While this cleans the nozzle's exterior, it's preferable to avoid having any material on it in the first place. As a result, think about increasing the Z offset and leveling the print bed. A silicone sock that covers the majority of the nozzle and prevents too much material from sticking could also be beneficial.

- Clogs

Clogs are perhaps the most prevalent nozzle problem. They happen when debris at the hot end stops the nozzle's output hole, preventing filament from escaping, (this results in under extrusion or worse missing prints). Partially clogged nozzles and fully clogged nozzles are the two forms of nozzle blockages. Full clogs, as you might expect, are the worst kind of clog. Debris completely clogs the output hole, trapping filament inside the extruder. When material just blocks part of the exit hole, partial blockages occur. If you have either, even if it's not as terrible as full clogs, you should clean your nozzle.

Solutions

There are various ways to clear nozzle blockages, and we'll go over two of them here.

- Preheat the printer to the filament’s melting temperature.

- All printers come with a needle that is used to unclog the nozzle. The first and most straightforward method is to break up and push the debris out of the way. Push the filament upwards with the needle through the opening in the nozzle, then take the needle out (repeat multiple times).

- The second way is to use a cold pull, which completely removes the debris from the hot end. A cold pull is exactly what it sounds like: you take the filament out of the printer without sufficiently heating the nozzle, allowing the cold filament to pick up whatever material is blocking the nozzle. This method is a wonderful way to get rid of most of the dirt and dust that may have accumulated within the nozzle and that you couldn't get out using the needle method.

- Cleaning the nozzle mechanically

While this is likely the best method, keep in mind that you'll need a heat gun or some other method of seriously heating up the nozzle to the point where the plastic inside softens a little, some long nose pliers, and the same needles we mentioned earlier (the ones that usually come included with the printer).

- Set the heat gun to a low temperature and place it facing upwards on your work surface (desk).

- Place the nozzle directly into the heat with the pliers until it is heated up.

- Remove as much contamination as possible using the needle and long nose pliers.

- Continue this procedure until the nozzle appears to be clean (look straight through it and if you can see that the opening is perfectly round, you should be good to go).

NOTE: Overheating hardened nozzles, may cause them to lose their hardened qualities and become damaged.

- Replacements and upgrades

If none of these cleaning solutions seem to do justice to the printing challenges that you face, it is most likely that your Ender 3 nozzle has degraded significantly and no amount of cleaning can help, it's probably time to get a new one. Your last resort is to replace your clogged nozzle entirely. Ender 3 nozzles are quite inexpensive; therefore, this procedure is painless in terms of cost.

- Start by heating the hot end to melt any solidified material caught in the nozzle for this approach. Also, remove any filament that has been fed into the extruder.

- Unscrew the nozzle from the hot end once the clogged filament has softened due to the heat.

- Clean the hot end with a small metal rod or pick to remove any extra filament stuck in the assembly before installing the new nozzle.

Conclusion

While cleaning a nozzle isn't difficult, preventing it from happening in the first place is far better than dealing with it later. Since dirt and dust buildup can cause the nozzle to clog, keeping the printer in a clean environment with less dust blowing around will help avoid dust buildup over time. Hopefully, this article has provided you with sufficient knowledge on the perfect ways to clean your Ender 3 nozzles.

Leave a comment