How to Turn a 3d Printer into a CNC Machine

No doubt a 3D printer is a really cool tool to have in the 21st century. You could make all sorts of stuff with it; from action figures to PCBs, toys, and even spoons. With a 3D printer, you could make almost anything, you’re only limited by your imagination. But what if we could do more with our 3D printer, what if we could convert it into something else, say a CNC machine? Is that possible? Emphatically yes!

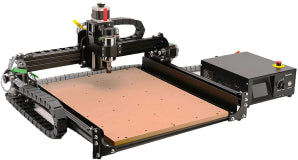

Well then, what is a CNC machine? CNC machines are making parts all over the planet for pretty much every industry. They are machining tools used to make things out of plastics, metals, aluminum, wood, and numerous other hard materials. The term "CNC" means Computer Numerical Control, although, today everybody calls it CNC.

Things being what they are, how would you characterize a CNC machine? All mechanized movement control machines have three essential parts -- an order work, a drive/movement framework, and a criticism framework.

CNC machining is the most common way of utilizing a PC-driven machine to create a section out of strong material in an alternate shape. So, let’s delve into the principle of how we can convert our 3D printer into such a machine.

How to turn a 3D Printer to CNC Machine

CNC machines are engraving tools used to engrave or make cut patterns on the surfaces of large blocks of materials. CNC machining can be used to produce parts that are strong and have precise dimensions. It is generally accepted as being the best for the manufacture of parts for airplanes and cars machinery, and some other fields where robust parts are needed.

A 3D printer is basically the same as a CNC machine, both electronically and mechanically. They move a tool around in three dimensions but reducing this to practice however causes some issues. A CNC tool typically weighs more than a HotEnd 3D printer and cutting into solid material generates a lot of torque. The two machines run G-code and move in three axes involving stepper motors- or engines with encoders on account of "genuine" CNC mills. The main significant contrasts are the force of the engines and the underlying inflexibility of the casings. However, for light-obligation etching in delicate materials, a 3D printer ought to be adequate.

You will require these parts;

- A DC brush motor (preferably 12volts)

- PVM DC motor controller

- Chuck and

- An engraving tool (Spindle)

- Spindle Mount

It’s necessary to use a DC brush motor because it is relatively easy to control the speed, you only have to control the voltage to control the common speed. It is not limited by frequency or power so it can be made into a high-speed motor. The CNC uses a very high-speed motor for its cutting action so the DC brush motor is very effective.

PVM DC motor controller will be used to control the speed of the DC brush motor and can be attached to the frame of the 3D printer. The chuck which will be used to hold the spindle is mounted on the motor. A four-jaw chuck is most preferred to a three-jaw chuck.

The extruder has to be removed from the printer as well as all the associated wiring like the heater cables and temperate probes which will make things a bit easier to deal with. Then in place of the extruder, you’ll need to put the appropriate spindle mount to hold the spindle firmly to the printer.

Next, you’ll have to change the print bed. The print bed holds the printed piece for a 3D printer but the material used to manufacture it is not sturdy enough if you’re going to place objects to be machined on it. Basically, a CNC is a machining tool so you’re not going to be needing the filament spool or the hot end of your 3D printer, those parts are to be taken out too.

Mount the DC brush motor on the spindle mount and attach the spindle to the chuck which will then be attached to the motor. The chuck ensures the spindle is firmly held. You will of course have to make proper connections between the motor and the PVC DC controller.

The next thing to do will be to remove all the internal wires that are not needed for the operation of the CNC machine. Of course, this will vary for different types of printers but it will ensure that the printer functions as a CNC machine without any errors.

After all these parts have been removed and the basic necessary parts for a CNC added to the printer, the X and Y motor axes of the printer are disabled because the CNC machine will only be working with the Z-axis of the 3D printer.

With the hardware part of your 3D printer ready, the next thing to consider is the G Code that will make your printer function as a CNC machining device. The G code for any work you’ll be doing for a converted 3D printer to CNC machine will only need to have depth so the width and height parameters will not exist.

The 3D printer and the CNC milling machine both use G code. Although some 3D printers do not have support for G code, if yours is one of them, you will have to find another suitable way to pass commands to make it function as a CNC machine. One way of doing this is to download and use a conversion tool to convert from .stl to G code file format.

The resulting device can be used to cut acrylic, wood, and even aluminum. The results will be good although not perfect. Another option will be to mount a laser (which doesn’t have torque problems) instead of a motor as lasers are a much better cutting tool than rotating spindles. This will of course have safety issues but that will be another hurdle to clear.

3D Printer or CNC Machine, Which Is Better?

The major difference between a 3D printer and a CNC machine is that 3D printing is a kind of additive manufacturing process while CNC is a subtractive manufacturing process. This implies that CNC machines start with a block of material called a blank and machines away parts of the material to produce the finished product whilst the 3D printer manufactures products by creating parts layer by layer using materials like plastic filaments or resins.

Both 3D printing and CNC machining are viable with a wide assortment of materials, including plastics and metals. 3D printing anyway is more centered around plastics, by and large, however, this is changing quickly as better and more reasonable methods of 3D printing metal are being created

Here are a few differences between 3D printing and CNC milling;

- CNC milling creates a lot of waste. 3D printing does not.

- 3D printers are better at creating more customized, unique products.

- With CNC milling, you can make a broad range of sizes — from tiny, delicate parts to car parts.

- Although they are slower at producing a component, 3D printers are flexible and can easily switch between jobs.

- CNC fits with large-scale manufacturing, so it can deliver a lot of higher results at a time.

- CNC machines can consistently produce a product the same way each time.

Can You Convert a CNC Machine into a 3D Printer?

While the reverse is relatively easy, converting a CNC machine to a 3D printer is a very big deal and extremely complex. CNC machines come with parts that are much faster than those of a 3D printer, trying to convert a CNC machine to one will cause several problems including accuracy issues. It is not advisable that you try to convert a CNC machine to a 3D printer, although you could use the parts of a CNC machine to replace some parts of a 3D printer.

The CNC machine is usually bigger in size as compared to the 3D printer, so the Z-axis is very large. It takes a long time to 3D print objects of relatively small sizes, so with the larger size of the CNC tool, if it is converted to a 3D printer, what you’ll have is a really big 3D printer that cannot be used to manufacture large objects because it is going to take an almost infinitesimal amount of time.

For this reason, it is not a very good practice to convert your CNC machine into a 3D printer.

Conclusion

There are some basic similarities between the 3D printer and a CNC machine like the fact that they both make 3D products from 3D models by following instructions from a computer, this makes converting your 3D printer to a CNC machine relatively easy. Although a 3D printer cannot be a substitute for the CNC machine, it nonetheless makes itself useful as a cheap and quick substitute for a CNC and it is also a good DIY project if you’re looking to get your hands dirty.

Leave a comment